On the chilly night of December 03rd, 1984 around 12:00 A.M workers who were working in a chemical factory at Bhopal sensed some fishy smell was coming from one of the chambers and also saw some yellow liquid dripping from the pipe. Around 12:45 A.M smell got really strong, Workers started coughing and scratching their eyes. In the next 2 days, thousands of innocent citizens who were living peacefully in Bhopal died a gruesome death… This is the story of one of the worst industrial disasters that ever happened on this planet. This is the story of Bhopal Gas Tragedy …

Backdrop of Bhopal Gas Tragedy

In the year 1969, a company named Union Carbide started a factory in Bhopal to produce a special insecticide called ‘Sevin’. Union Carbide was more than 100 years old. The company is famous for other products like Eveready batteries, bakelite, pesticides, and also rocket fuels. 49% stock of the company was with investors which include the Government of India. The factory which started in Bhopal was mainly focused to produce Sevin which is used for the betterment of crops. For the making of Sevin a chemical is used which is called MIC (Methyl Isocyanate) It is a deadly chemical and was not easily available in India So UCIL (Union Carbide India Ltd) started importing MIC to make Sevin.

In the year 1980 UCIL incurred huge losses, so the company shifted from its original decision and decided to make MIC in India itself so that import costs could be cut. In the same year, Government told UCIL that a proper evacuation plan should be drafted for proper evacuation of people in case of any mishappening in the plant, but the company never drafted it. In 1981 a worker died because of exposure to MIC but no action was taken by the company.

In the coming years, Sevin sales went down because many competitors company cropped up that had cheaper products. So UCIL decided to cut the cost of Sevin to make it cheaper and to do so, they had to cut costs at many places. Many irregularities started happening in UCIL some were,

- The workforce was reduced to a significant extent.

- New workers were underqualified.

- Safety precautions were ignored to save money, for example, if pipes were found damaged they’d be repaired by unsafe methods rather than replaced.

- Regular leaks took place, and workers were getting worried.

- Neither residents of Bhopal nor the worker working at the factory knows about how dangerous MIC was.

- Trade unions in the area started protesting but the union leaders were removed from their jobs.

A resident of Bhopal was very curious to know the exact details of the plant; He was a friend of Mohammad Ashraf. Mohamad Ashraf was the same guy who died in 1981 due to exposure to MIC. Before his death, Ashraf told his friend about his worries and about the condition of the plant. He was concerned about the safety of the factory. Ashraf told his friend Mr. Rajkumar Keswani who was a journalist by profession about the condition of the plant, Rajkumar began investigating it and he prepared a report by himself about the tragic condition of the plant. His report was titled ‘Bachaiye Huzoor, is Sheher ko Bachaiye’(Save the City). His report mentioned a huge disaster could happen because 20 % of the population of Bhopal was living near the UCIL factory.

Journalist Rajkumar did not have any scientific knowledge about the chemicals, He read it somewhere that Phosgene gas was being used at the plant and it is the same gas that was used by Nazi Germany in ‘Gas Chambers’ during World War II. He then realized the severity of the danger. He even wrote to the Chief Minister and The Supreme Court of India but did not get any response.

The science behind Bhopal Chemical Plant

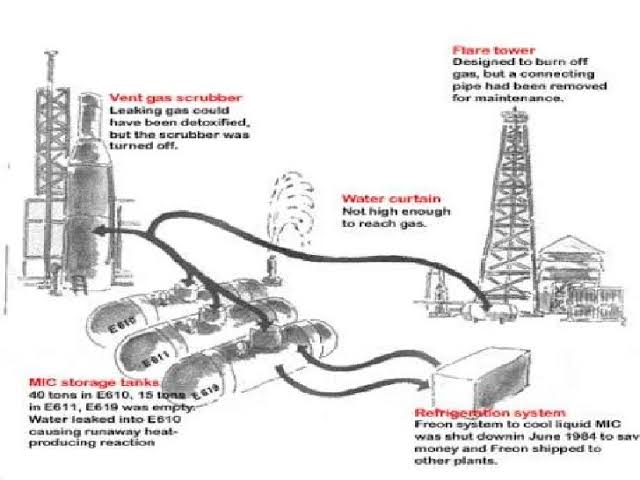

MIC was stored in liquid form in 3 huge tanks underground (E610, E611, and E619). Tanks E610 and E611 were filled with MIC and E619 was supposed to remain empty for emergencies. The tanks were supposed to be filled with MIC for 60% of the volume of the tanks only. MIC+H2O(Water) has a very dangerous reaction, if MIC gets in contact with water or even air their reaction releases a poisonous gas. To avoid this, in every tank MIC was covered with pressurized Nitrogen so that it remains safe in its place. The pressure and temperature of the tanks was being checked regularly. Two outlets or pipes in every tank were placed, One to exhale poisonous gas which was eventually burned off in a chimney using Vent Scrubbers, and the other was an inlet of Nitrogen.

Mistakes of UCIL

- Tanks that are supposed to be filled with 60 % of their capacity were filled with more MIC; also the third tank which was supposed to remain vacant was not empty. More than the approved amount of MIC was stored in the plant to save money

- The indicator which shows the level of MIC was not working

- The pressure of two out of three tanks was not right.

- An Alarm was installed in the factory which was supposed to set on if the temperature goes high, but it was disconnected years ago.

- The pressure valve in the E610 tank which was used to monitor pressure inside the tank was not working and no one had repaired it.

- There were two alarms for any mishappenings, the first one to alert the workers and the Second one to alert the residents of Bhopal which was switched off.

- The company had almost closed off its operations, but MIC was still there for use to make Sevin

Timeline of Bhopal Gas Tragedy

09:00 P.M: The workers had a shift change and new workers came in Union Carbide. They started their routine work. They started washing the pipes attached to MIC tanks with water but they noticed that water was not coming from the other end, so they started cleaning the filters assuming that the water was getting clogged after that they repeated the process but still, water was not coming out of the other end of the pipes.

10:00P.M: Water started entering in E610 tank because a slip band which was being used to protect water from entering the tank was missing. Reactions started happening, A cloud of gas started forming inside the tank but the workers were unaware of this and they did not know any such thing due to lack of scientific knowledge.

11:00P.M: The workers went to their supervisor. The supervisor told the operator to let the water flow and that the workers of the next shift would turn off the water.

12:00 P.M: New workers arrived and realized that their eyes were burning. They checked the pressure of the tanks, the pressure was just above normal, and they deemed it to be safe. But, they also figured there was a leak somewhere as their eyes were constantly burning so they started looking for the leak.

12:10 A.M: One of the workers Mr. Suman Dey while looking for a leak saw some liquid dripping from one area.

The exact events of the next hour are still debatable but it is still believed that workers ignored the leak and went for a tea break till 12:40 A.M, but some experts believed that the panic had begun before that. The blame was put on some supervisors and workers because they did not take gas leaks seriously.

12.30 A.M: The workers realized that a major accident had occurred there. The pressure reading was very high. Suman went to the control room to switch on the alarm and turn off the water that was flowing in the MIC tank but it was too late.

The poisonous gas went through the Vent gas scrubber which was used to burn out the poisonous gases but as the amount of gas was too high Vent gas scrubber just stopped working. The workers tried to spray water on the releasing gas but the chimney was at a height and water just could not reach there.

01:00A.M: Situation went out of control. The workers started evacuating the factory

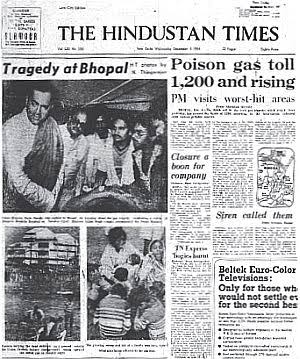

01:30A.M: Gas spread out to most parts of the city. People were coughing, many people came out on the streets, and many opened doors and windows causing more of the gas to enter their homes. Most of these people lived in slums surrounding the factory. People compared the smell of gas to burning chilies. Some people were killed in their sleep others died by coughing and struggling to run away from it. The sick were taken to the hospital nearby but the doctors were not aware of how the symptoms were supposed to be treated. Some doctors gave oxygen to the patients but actually large amount of oxygen reacts badly with the gas. Many patients died in the hospital.

By the next morning, thousands of people have died. Dead bodies of animals were all over the streets and Bhopal gas tragedy becomes India’s worst Industrial Disaster.

Steps Taken Next Day

Union Carbide sent their technical team to India to convert the remaining MIC into a less dangerous gas. This operation was named ‘Operation Faith’. Union Carbide Company sent money as a relief measure. Warren Anderson who was the chairperson of UCIL at the time took the responsibility into his own hands. He was arrested the next day.

Legal Action

In 1985 an Act was passed in the Parliament which empowers the Government of India to represent the people of Bhopal in court. An investigation was needed for court cases so both UCIL and GOI conducted the investigation separately. Both agreed that the actual cause behind the accident was the reaction of water with MIC.

GOI claims that UCIL was at fault as they did not train their staff. Their safety standards were not maintained properly, because of which water leaked into the tank.

UCIL claimed GOI was at fault that they did not allow UCIL to make changes in safety design and that the staff working at the plant was at fault, not the company itself. Staff sabotaged the plant and intentionally put water into the tank. In 2003 Ingrid Eckerman, Doctor who was studying the Bhopal gas tragedy in detail wrote in her book that the court did not find any evidence of any sabotaged.

The court case ended in 1989 UCIL decided to pay 470 million dollars to GOI as compensation. But the residents of Bhopal believed compensation was not justice.

In February 1989, Satish Dhawan (Former ISRO Chief) filed a petition to protest against it and the case reopened in the Supreme Court of India as a Criminal case. Warren Anderson and the workers present were accused by the court as the main offenders. UCIL and Warren Anderson were declared criminals. The Indians who were accused in Bhopal gas tragedy paid a fine. Warren Anderson did not appear in the court himself. He died of natural causes in 2014.

Many Acts were passed after this incident to safeguard against the threat of such disasters like the Environment Protection Act, and Amendment to Factories Act. Many years have passed but the victims of Bhopal gas tragedy are awaiting justice even today…